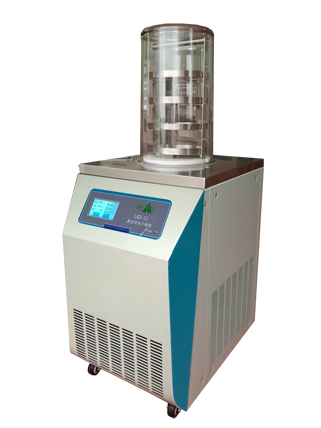

1.2L Laboratory Freeze Dryer

LGJ-12 manifold top press freezing dryer is suitable for freeze-drying experiment in laboratory or a small amount production. So they may meet some conventional needs of laboratory.

1. Green and environmental protection in line with international standards

2. LCD display, Chinese interface, display drying curve

3. The cold trap has a large opening, no coil inside, and has a pre-freezing function

4. Imported compressor with strong water absorption capacity and low noise

5. The pre-cooling rack can be used as a drainage tube to speed up the drying speed

6. The cold trap and operation panel are made of stainless steel, which is corrosion-resistant and bright

7. The transparent bell-shade drying room is safe and intuitive

8. Stainless steel sample rack, the space of ordinary sample tray can be adjusted

9. Small size, easy to operate

10. Optional nitrogen valve.

| Model | NBJ-12 series vacuum freeze dryer | |||

| Standard type | Standard manifold | Top-press type | Top-press manifold | |

| Freeze-dried area | 0.12㎡ | 0.08㎡ | ||

| Material plate size | Ф200mm | Ф180mm | ||

| Number of material trays | 4 | 3 | ||

| Material plate spacing | 70mm | |||

| Eggplant bottle | - | 100/250/500/1000ml bottle each | - | 100/250/500/1000ml bottle each |

| Cold trap temperature | ≤ -56 ° C (no load), optional ≤ -80 ° C (no load) | |||

| Cold trap depth | 240mm | |||

| Cold trap diameter | Ф215mm | |||

| Water catching capacity | 3-4kg/24h | |||

| Pumping rate | 2L/S | |||

| Ultimate vacuum | ≤5pa (no load) | |||

| Installed power | 970W | |||

| Host weight | 62kg | |||

| Mainframe dimensions | 580×500×720mm | |||

| -80 °C mainframe dimensions | 770×550×720mm | |||

| Drying chamber size | Ф260×430mm | Ф260×490mm | Ф260×465mm | Ф260×540mm |

| Cooling method | air cooling | |||

| Defrost mode | naturalized cream | |||

| Plate loading material | 1.2L (material thickness 10mm) | 0.8L (material thickness 10mm) | ||

| Vials quantity | - | - | Ф 12mm: 492 | Ф 12mm: 492 |

| - | - | Ф 16mm: 297 | Ф 16mm: 297 | |

| - | - | Ф 22mm: 147 | Ф 22mm: 147 | |

| Model | Application difference |

| NBJ-12 Standard type | Suitable for freeze drying of conventional materials in bulk (liquid, paste, solid) |

| NBJ-12 Top-press type | It is not only suitable for the freeze-drying of conventional materials in bulk (liquid, paste, solid), but also suitable for the drying of the bottled materials of vial. When preparing for lyophilization, the materials are dispensed into the vials as needed, and the caps are floated and frozen. Drying, after the end of drying, the capping device is pressed tightly to avoid secondary pollution, re-adsorb moisture, and easy to store for a long time. |

| NBJ-12 Standard manifold | It is suitable for freeze-drying of bulk (liquid, paste, solid) conventional materials, and can be used to pick up the flask outside the drying chamber to dry the material that is frozen on the inner wall of the bottle. At this time, the flask is used as a container to be connected to the outside of the drying oven. On the tube, the material in the flask is heated at room temperature, and the multi-manifold switch device can be used to remove or load the flask as needed without stopping. |

| NBJ-12 Top-press manifold | On the basis of the common type characteristics, it combines the characteristics of the gland type and the multi-tube type.

· Suitable for freeze drying of conventional materials in bulk (liquid, paste, solid); ·It is suitable for the drying of the bottled materials of Xilin. When preparing for lyophilization, the materials are packed into the vials as needed. After the caps are floated, the caps are freeze-dried. After the drying, the capping device is pressed to tighten the caps. Contamination, re-adsorption of water, easy to preserve for a long time; ·The flask is attached to the outside of the drying chamber, and the material frozen on the inner wall of the bottle is dried. At this time, the flask is connected as a container to the manifold outside the drying box, and the material in the flask is heated at room temperature through a multi-manifold switch device. The flask can be removed or loaded at any time as needed without downtime. |